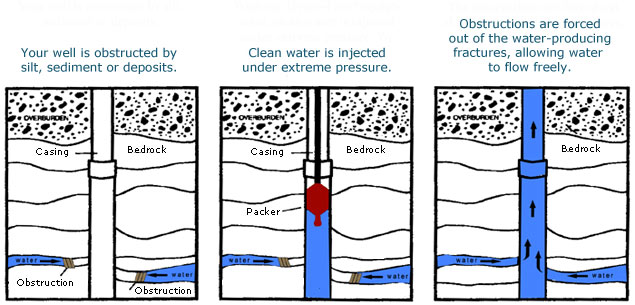

The Well Fracturing Process

Our Services

The procedure involves the installation of an inflatable packer that is placed in the well bore at least 20 feet below the well casing seal, and at least 60 feet below the ground surface. This insures that the process does not “break” the seal or allow surface water contaminants to enter the well. The packer is inflated into position and water is pumped through the packer under pressure. Most applications require between 500 and 2,000 pounds per square inch (psi) pressure and in some cases 3,000 psi pressure may be needed in tight rock formations.

If successful, pressure will steadily rise to a maximum level as the rock formation resists flow, then will drop off and stabilize at a lower pressure. The drop in pressure indicates that the formation is accepting water and the resistance to flow is diminished. Water is pumped into the formation for 5 – 30 minutes. Injection pump delivery rates of 50 – 75 gallons per minute (gpm) have proven successful. Generally, 1,500 – 2,000 gallons of water of more are pumped into the bedrock formation.

It is extremely important that only potable water, or clear disinfected water, is used for injection water because of the high pressures involved and potential for forcing contaminants deep into the bedrock fractures.

One or two packers may be used for well fracturing. When utilizing one packer, the packer is set near the top of the well but a minimum safe distance below the casing seal. After the initial pressurization sequence, the packer is released and lowered further into the hole, and the process is repeated as many times as necessary. Commonly, two pressure sequences are performed.